Extruded Aluminium Profiles automatic packaging line

Vimetco Extrusion, € 3.8 million project. Reduced CO2 emissions, less waste in the manufacturing process

Vimetco Extrusion has completed the implementation of a project worth over € 3.8 million. The project involved the purchase of an automatic packaging line for finished products, an investment that will lead to a reduction in CO2 emissions and a reduction in the amount of waste generated in the production process.

The project `Extruded Aluminium Profiles automatic packaging line` was financed with the support of grants from the Norwegian Financial Mechanism 2014-2021 within the program `SME Development in Romania`, Focus Area: Green Innovation in Industry, Blue Growth and ICT, according to the Financing Contract number 2020/548499, concluded with Innovation Norway as program operator.

A € 1,851,000 grant

The implementation of the project aimed to increase the competitiveness of Vimetco Extrusion by introducing `green` aluminum manufacturing processes, the specific objective being to achieve process innovation through the acquisition of an automated packaging line for finished products. The project ran from July 2021 to April 2024 and had a total value of €3,849,311, of which €1,851,000 was grant funding.

The implementation of the project aimed both to increase the company's turnover and to reduce CO2 emissions, reduce fuel consumption and waste produced in the manufacturing process.

The project was carried out in partnership with International Development Norway (www.id-norway.com), a Norwegian consulting company specialized in green innovation in industry.

Contact data:

Vimetco Extrusion

Project Manager: Stefania Yaksan

e-mail This email address is being protected from spambots. You need JavaScript enabled to view it.

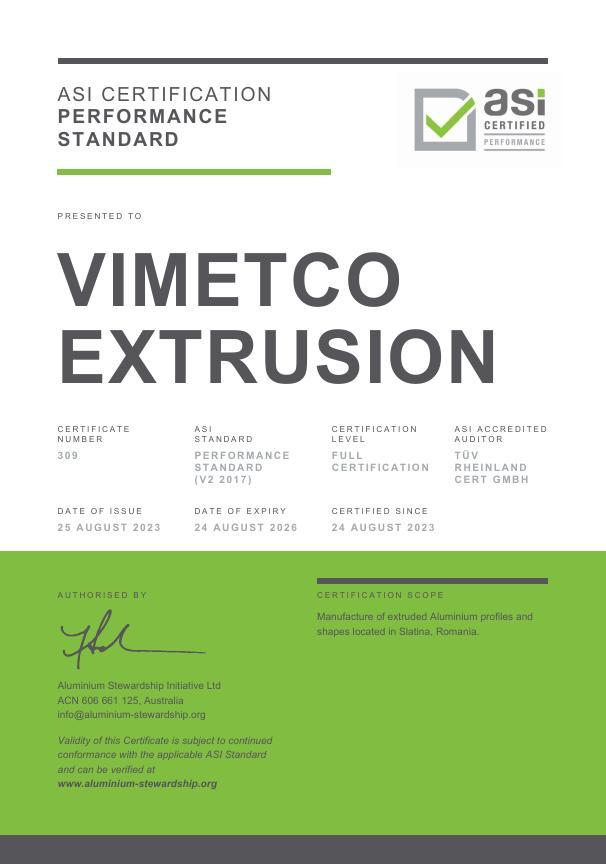

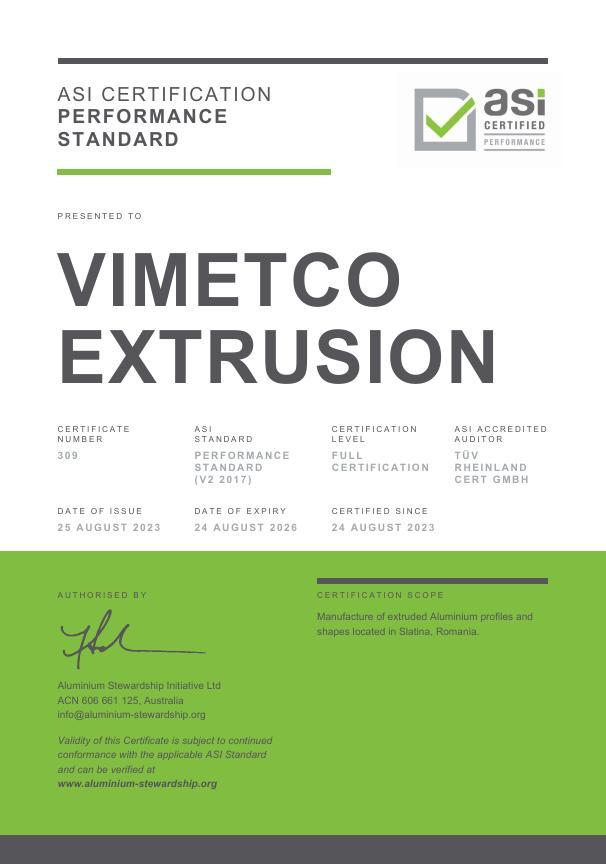

SC Vimetco Extrusion Srl has achieved ASI Performance Standard V2 (2017) Certification for the manufacturing of extruded aluminium profiles and shapes at its facility at Slatina, Romania. The plant is equipped with three extrusion lines, with the facility capable of producing up to 35,000 tonnes annually. Aluminium Stewardship Initiative (ASI) today announced that SC Vimetco Extrusion Srl has been certified against the ASI Performance Standard. The company produces extruded products and shapes for the building and construction, solar, automotive and transportation sectors, as well as broader industry applications. The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The ASI Performance Standard (V2) defines environmental, social and governance principles and criteria, with the aim to address sustainability issues in the aluminium value chain. It sets out 59 criteria under the three sustainability pillars of Environment, Social, and Governance, which address key issues such as biodiversity, labour rights, Indigenous Peoples rights, and greenhouse gas emissions.

SC Vimetco Extrusion Srl has achieved ASI Performance Standard V2 (2017) Certification for the manufacturing of extruded aluminium profiles and shapes at its facility at Slatina, Romania. The plant is equipped with three extrusion lines, with the facility capable of producing up to 35,000 tonnes annually. Aluminium Stewardship Initiative (ASI) today announced that SC Vimetco Extrusion Srl has been certified against the ASI Performance Standard. The company produces extruded products and shapes for the building and construction, solar, automotive and transportation sectors, as well as broader industry applications. The ASI Certification program was developed through an extensive multi-stakeholder consultation process and is the only comprehensive voluntary sustainability standard initiative for the aluminium value chain. The ASI Performance Standard (V2) defines environmental, social and governance principles and criteria, with the aim to address sustainability issues in the aluminium value chain. It sets out 59 criteria under the three sustainability pillars of Environment, Social, and Governance, which address key issues such as biodiversity, labour rights, Indigenous Peoples rights, and greenhouse gas emissions.